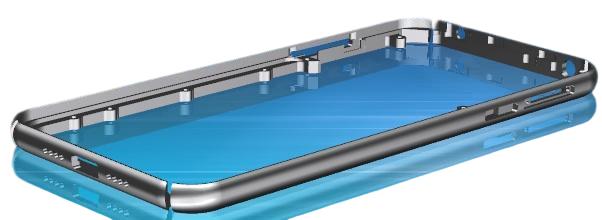

The stainless steel phone frame refers to the middle part of the phone case made of stainless steel material, which usually serves to support and protect the internal components of the phone. Stainless steel is widely used in the design of high-end smartphones due to its corrosion resistance, high strength, aesthetic durability, and other characteristics

The high strength and hardness of stainless steel materials result in increased cutting force and cutting temperature during processing. Accelerate tool wear and reduce tool lifespan

The chips of stainless steel are usually in the form of slender filaments, which are difficult to handle and eliminate, and can easily cause blockage in the cutting area, affecting the machining quality

Stainless steel is prone to work hardening during the cutting process. This phenomenon can lead to increased wear of the tool when cutting in the hardened area

Due to the high melting point elements and high plasticity of stainless steel, tool wear is severe during cutting, resulting in frequent sharpening and tool changing, thereby affecting production efficiency

During the cutting process, it is easy for chips to bond with the tool, forming chip lumps that affect the surface quality of the machined surface

In response to the difficulties in stainless steel processing, our company designs cutting tools from the following perspectives